Auto Bumper Injection Mold/Plastic Bumper Mould

Technical information for Car rear bumper mould Design software:UG Mould cavity: single cavity Molding material: PP, ABS

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | JMT2021396 |

| Application | Car |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1year |

| Transport Package | Wooden Case |

| Trademark | JMT |

| Origin | China, Zhejiang, Taizhou |

| HS Code | 8480710000 |

| Production Capacity | 650 Set/Year |

Product Description

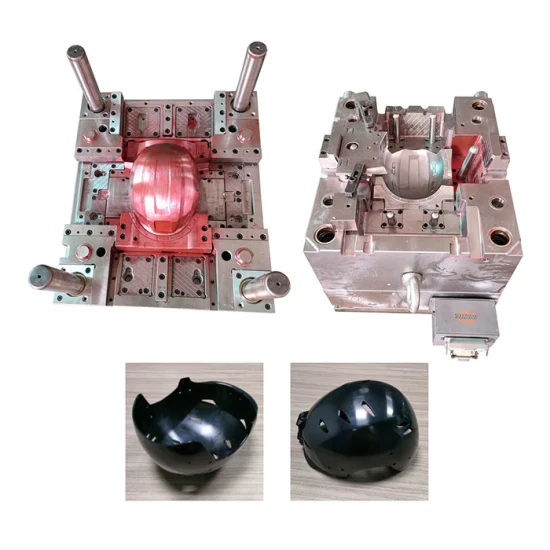

Technical information for Car rear bumper mould- Design software:UG

- Mould cavity: single cavity

- Molding material: PP, ABS, PE

- Mould cavity and core steel: 1.2738, P20, P20HH, 718H

- Hot runner system: Synventive, Yudo, HRS, Moldmaster

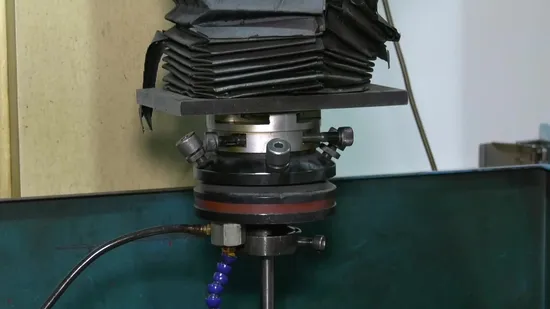

- Ejection system: Ejectior pins, angle lifters

- Leadtime: 90 days

- Mould life: 500000 shots to 1000000 shots

- Mould packing: wooden box

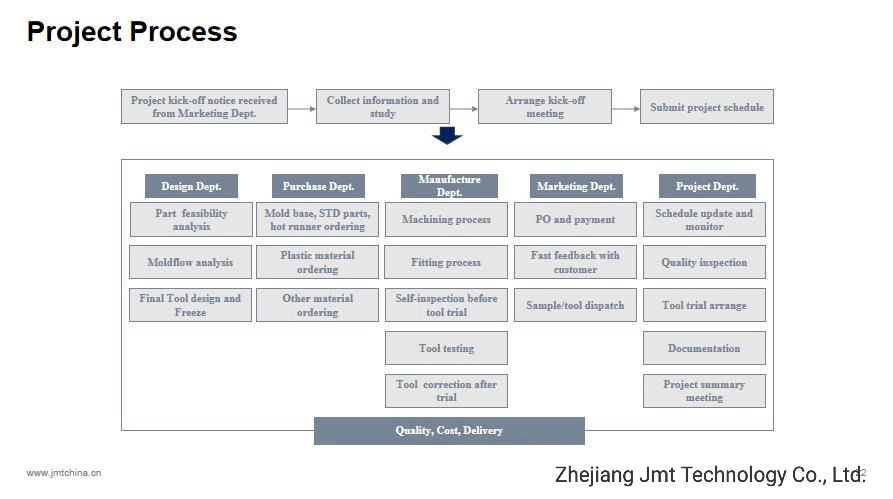

JMT Technology Service Scope to manufacture car bumper mould

- Plastic bumper product DFM analysis

- Moldflow analysis

- Plastic car bumper mould design

- Plastic car bumper mould assembly drawing

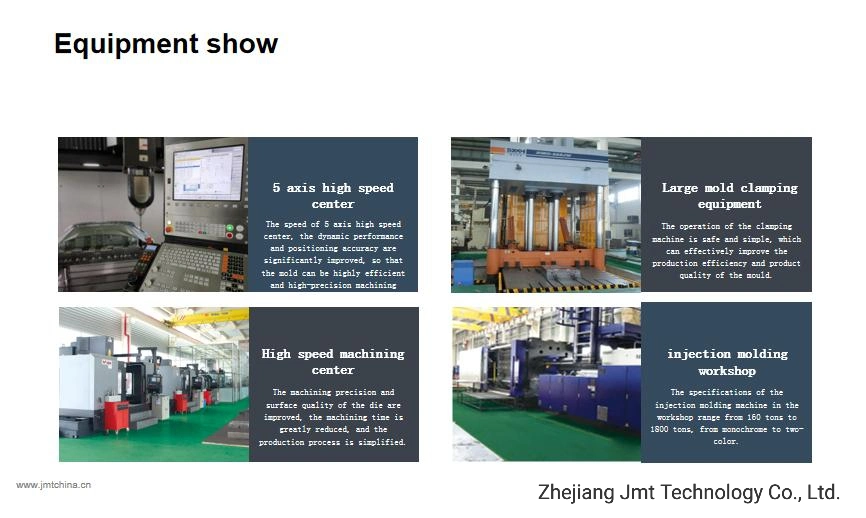

- Plastic car bumper mould machining

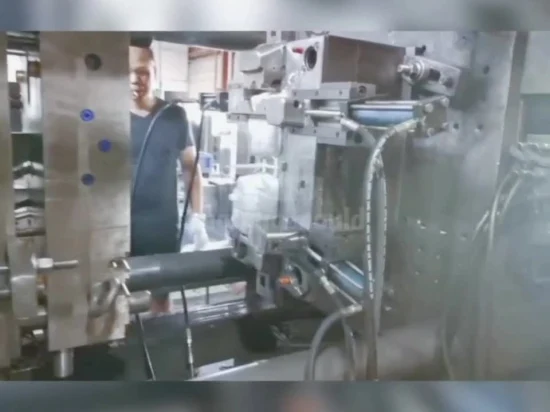

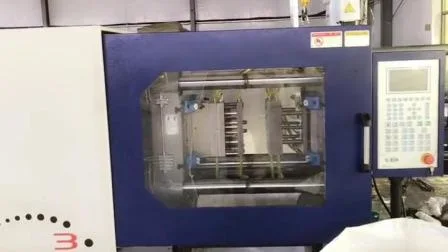

- Plastic car bumper mould testing via injection molding machine

- Plastic car bumper mould packing

- Plastic car bumper samples packing

- Mould spare parts preparation

- We also support you for protogype mould design and manufacture

Zhejiang JMT Technology Co.,Ltd specializes in designing and making auto parts, home appliance, kids electric car and household moulds. From 2005 until today, JMT Mould has had many great achievements in plastic mould development and manufacturing. Today, JMT Mould has over two hundred workers, including a mold design team of over 42 engineers. JMT Mould has organized their facility for efficiency using the latest principles of lean manufacturing. Their capabilities now include prototyping, an injection workshop and a state of the art QC lab. To help realizing the benefits of consistent quality systems and business practices, JMT Mould invested the time and effort to be awarded the ISO/TS 16949: 2009&tISO9001-2015 Quality Certification.JMT Mould has grown into a superior mold manufacturer with a strong engineering team. Engineering work includes not only mold designs, but also mold feasibility, mold flow, product design expertise and prototyping services. These allow the most efficient mold strategies to be developed for our customers. We have developed great relationships with customers such as VALEO, MAHLE GROUP, GOODBABY GROUP, by always providing excellent service. We are proud of our culture of continuous improvement and welcome all customers and potential customers to visit our factory anytime.