Injection Mold for Storage Bin Commodity Shelf

Plastic Injection Mould for Storage BinCustomized Molded Parts:This product/mould is Customized. If you would like to ha

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | GV-mold |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Semi Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| Capability | 500 Sets Per Year |

| Transport Package | Plywood Case |

| Specification | As per request |

| Trademark | GVI |

| Origin | China |

| HS Code | 8480710090 |

| Production Capacity | 500 Sets Per Year |

Product Description

Plastic Injection Mould for Storage BinCustomized Molded Parts:This product/mould is Customized. If you would like to have a custom made product/mould, just follow these steps.

| Steps | Information |

| 1 | Sample |

| Please contact and inform me if you would like to send a product sample. | |

| 2 | Mould requirements |

| Cavity. If not sure, pls tell me your Estimated Annual usage, and our designers could suggest appropriate cavity. | |

| Mould life. A suitable mould material is based on it. | |

| Product material. Which type of plastic, such as PP,PC,HDPE? | |

| Mould making time. In general, mould making time is 20~45 working days, if rush order, pls inform me. | |

| 3 | Quotation |

| According to your requirements, I will send a quotation list in 1~2 workdays after we check and confirm the optimum solution for you. | |

| 4 | Feedback |

| It will be highly appreciated if you give me your feedback without delay. So that we can improve our service. | |

| 5 | Continue Cooperation |

We offer services tailored for you and mould from concept to reality.Company Introduction:

Our main business range includes:

| Automotive | Auto interior plastic case, Auto inner parts, Bumper, Door plate, Lamp shell, Instrument panel, auto connectors , Electrical switch; Car gear, Complete sets of motorcycle parts; | |||||||||||||

| Electronic | Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards, USB Connector, USB housing, Mobile phone plastic part, remote control, key-press; | |||||||||||||

| Mechanical | Motor support plastic part, Pump plastic part, mower plastic parts; | |||||||||||||

| Household | Fashion cup, Juice cup, Some small plastic parts; | |||||||||||||

| Home appliance | TV front cover, TV rear cover, Display cover, Air-conditioner or Refrigerators plastic parts, Washing machine part; | |||||||||||||

| Medical | Hollow fiber dialyzer, Deaf-aid parts, Medical instrument body plastic parts, Blood-pressure meter parts, Blood-pressure meter, Stapler. | |||||||||||||

Molded Parts:

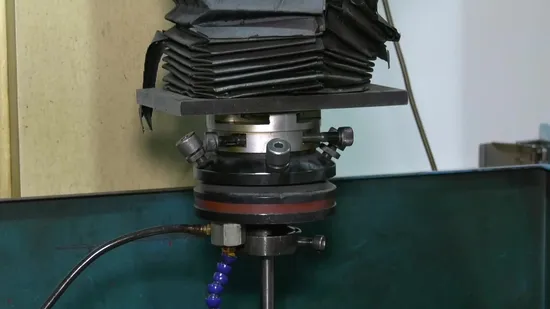

Some mold & structure in our workshop:

Package for molds:It's our pleasure if we are able to work with you to provide the value added service and help to make the optimum mold solution & product.

Related Products